Passion for sustainability, quality & responsibility

At Andersen & Stender we take responsibility. Responsibility when it comes to supply chain, products, and partnerships. We act properly in our business and partnerships as well as in our every-day interaction with people– but also when looking at the climate and the environmentally changes we do meet today and in the future. At Andersen & Stender we are aware about our global footprint, which is why we are consciously in choosing our partners.

We do believe that even little changes make a big difference. Therefore, we do focus on:

- Sustainable consumption & waste separation

- Local as well as global collaborations

- Our shipping methods. We always aim to find the most efficient route as well as mode of transport

We at Andersen & Stender constantly have sustainable products and workarounds in view. Thanks to L.I.F.E. we have succeeded in finding a way beyond galvanic corrosion/electroplating and thus are contributing to setting new standards within sustainable metal trim for the textile industry. With this groundbreaking technology we can produce and delivery eco-friendly snaps, jeans buttons, rivets etc.

By choosing L.I.F.E. we do ensure:

- Less harmful substances

- Fewer material inputs

- The elimination of heavy metals

- Less energy consumption

- Part of the electroplating process being replaced by mechanical and to great extent greener finishing processes

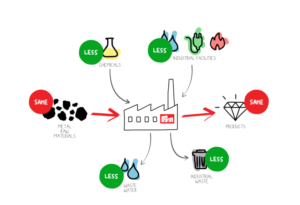

With the L.I.F.E. certified metal trim system by PRYM – PRYM ECOFINISH – we are capable of supplying everything within brass, copper, and stainless steel. Compared to the traditional working processes we are with PRYM ECOFINISH reducing our environmental footprint by:

- Water reduction by 65%

- Chemical reduction by 98%

- Harmful waste reduction by 85%

- Electricity reduction by 16%

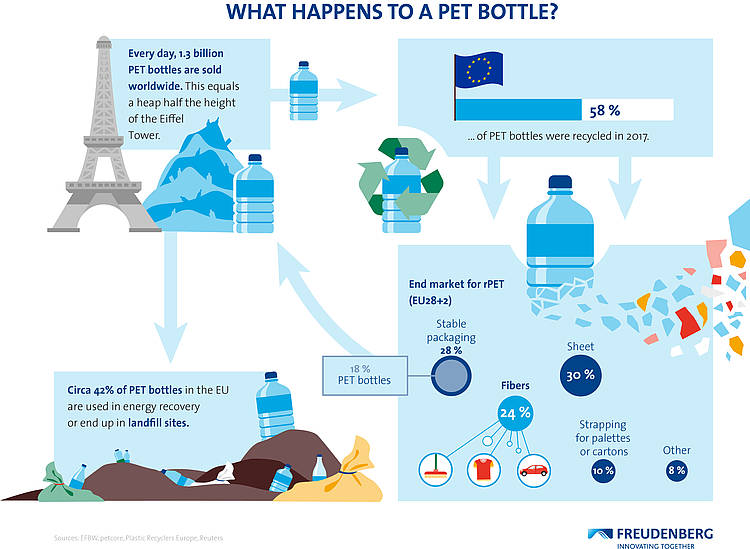

From recycled plastic bottles to snap systems

L.I.F.E. certified plastic snaps

We do emphasize the combination of responsibility and environment. Another interesting environmental development is plastic snaps: ECOWHITE, ECOGREEN & ECOBLUE.

ECOWHITE made of 100 % recycled plastic.

ECOGREEN made from plant-based renewable resources as e.g. potato starch. ECOGREEN snaps thus are 100% biodegradable.

ECOBLUE made from recycled plastic ocean waste.

With L.I.F.E. certified snaps we not only do focus on raw materials, the product, and the production but also do consider the processes beyond the product itself. For example, production place, packaging, distribution, consumption and waste disposal.

L.I.F.E. Circle – the circular choice

Pure raw materials ensure the recyclability

Do circular thinking interest you as it does to us? And thus, ensuring the design process and product to be more environmental? Recyclability and circular processes are just where you want to start. Within our L.I.F.E. certified program in the metal trim and plastic snap segment we do focus on pure raw materials. By doing this, the possibility of recycling the single materials in closed circular economy programs becomes possible.

- Pure raw materials

- Recyclability

- Circular economy programs

PRYM does with the L.I.F.E. certified snaps not only emphasize raw materials, the product and the production but also does consider and act on parameters as production place, packaging, distribution, consumption, and waste disposal. All having a big importance for and effect on the environmental and global footprint.

Let’s make it easy to expand your sustainability…

Recycled fibers turn into interlinings

Sustainable as close to the skin as it gets… At Andersen & Stender we guide you in and supply you with the best interlinings and waddings on the market. Our product range is produced by Freudenberg and the products are made by recycled fibers. Freudenberg does take pride in and value sustainability highly and thus has a strong sustainable profile. The green products and profile of Freudenberg are essential for our partnership.

We support and guide you in taking the step to achieving a 100% sustainable product. Our interlinings are exceptional… not only in keeping the shape of your product but also in shaping your environmental footprint and thus the future. The following parameters are relevant to underline:

- 90% of our interlinings are made of recycled PET-bottles.

- Our Waddings are strong isolating alternatives to down and feathers

- Broad range of biodegradable and organic interlining

- Focus on water recycling

- Adhesive technology with low melting temperatures ensuring lower energy consumption